工作原理

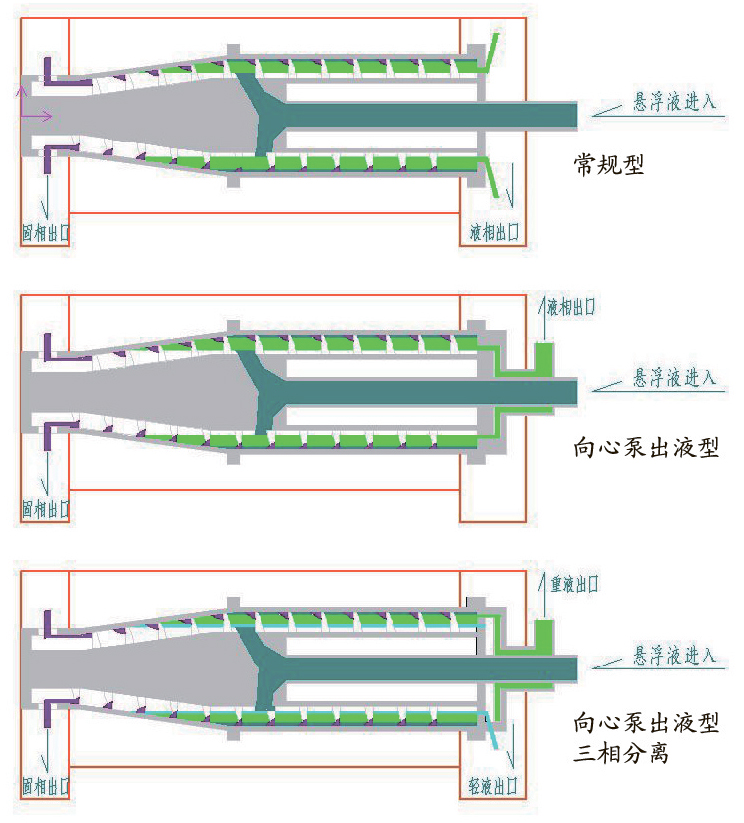

悬浮液通过进料管进入转鼓内,在离心力场作用下密度较大的固相沉降至转鼓壁上,固相在螺旋的推动下从沉降区至干燥区后从出渣口排出;澄清的液相从转鼓大端溢流口溢出,实现固液分离。

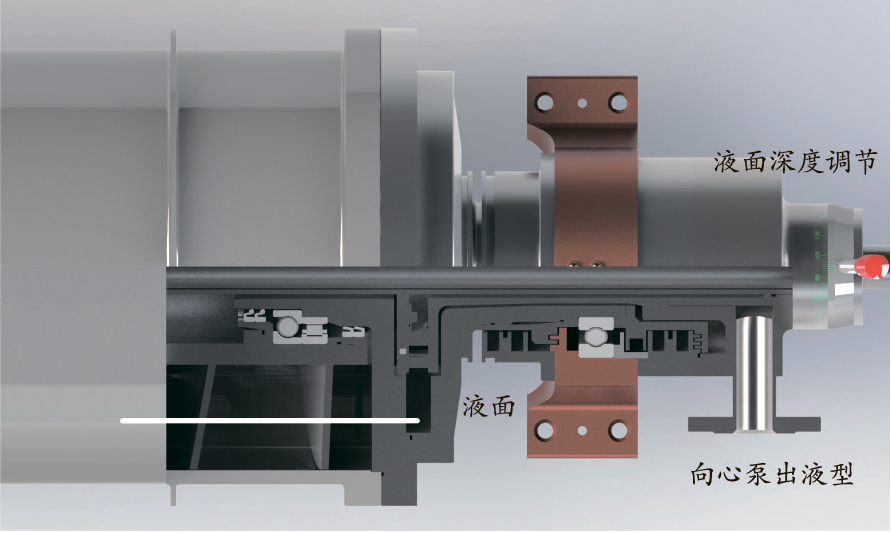

LWX为向心泵出液型。

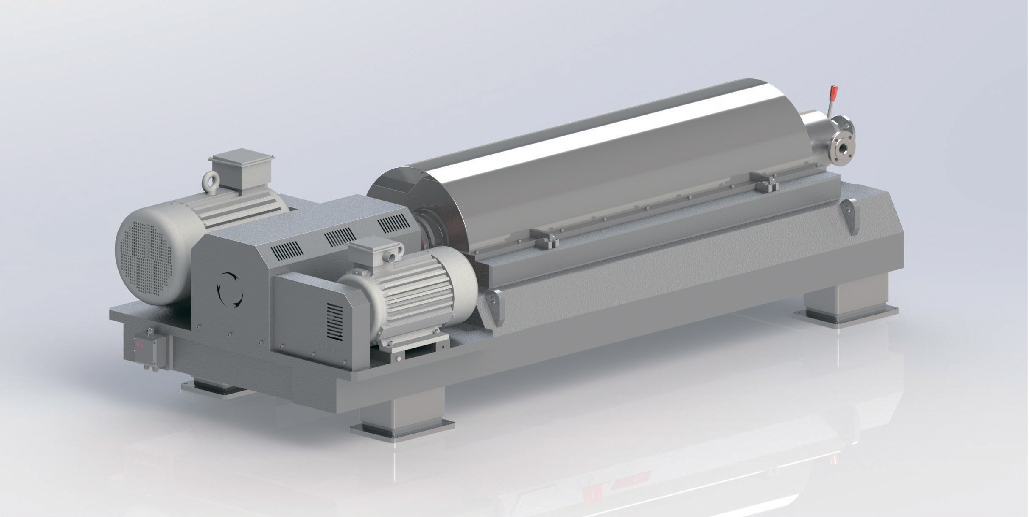

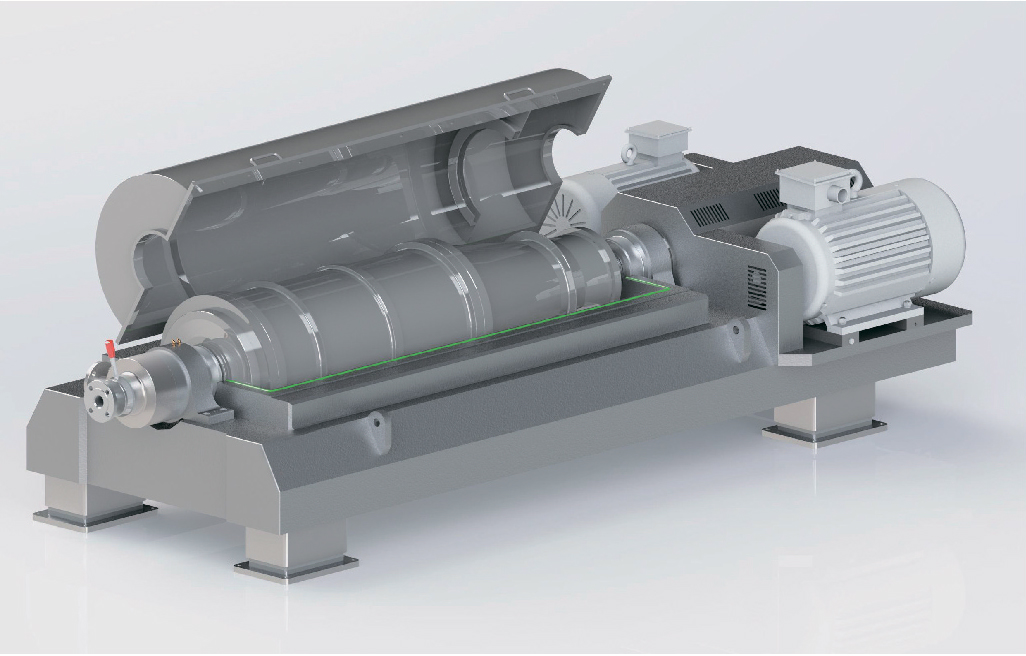

LWX外形图 LWX Outline drawing

主要特性

u 转鼓、螺旋等与物料接触部分材料按使用工况选择相应的耐蚀不锈钢、双相钢或C22

u 高精度转鼓(数控加工、高精度平衡),高分离因数,提高分离效率

u 双变频共直流母线控制,转鼓、螺旋转速无级调整

u 多种润滑方式:脂润滑(标配)、喷油润滑、油气润滑

u 全自动加油装置

u 螺旋叶片表面喷涂耐磨合金或镶焊硬质合金

u 对应不同的工况,选择适合的差速器:摆线针轮、行星齿轮或液压差速器

u 系统全密闭,满足清洁生产要求

u 多重保护:过振动保护,开盖保护,电机过载保护,差速/转矩控制切换,轴承温度检测,螺旋推料扭矩保护,静电接地保护,检修锁定保护

u 配置氮气保护系统以及相应的防爆措施,满足防爆要求

u 可集合絮凝剂加药系统、螺杆泵、流量计等,组成全套污水处理系统

定制形式 Personal form

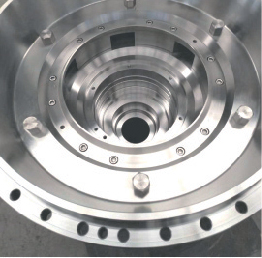

转鼓离心铸造

u 转鼓整体离心铸造、固熔处理,比较好的稳定性

u 更高的强度

u 多种材质304、316L、2205、C22、C276

Centrifuga casting of rotor drum

u The rotor drum is made by means of centrifugal casting and solution treatment,which means better stability

u Higher strength

u Can be made of various material including 304、316L、2205、C22、C276

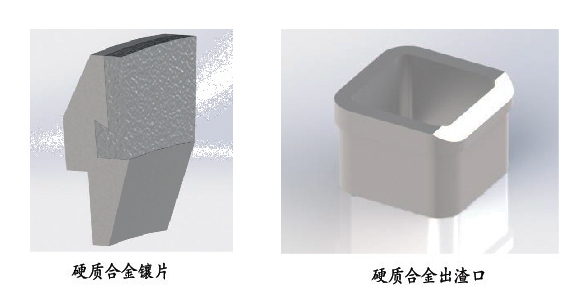

螺旋耐磨处理

u 硬质合金镶片

碳化钨合金

镶嵌结构

u 表面硬质合金喷涂

推料面碳化钨合金喷涂

Screw wear-resistance treatment

u Cemented carbide insert

Tungsten carbide alloy

Built-in structure

u Cemonted carbide coated surface

Tungsten carbide coated

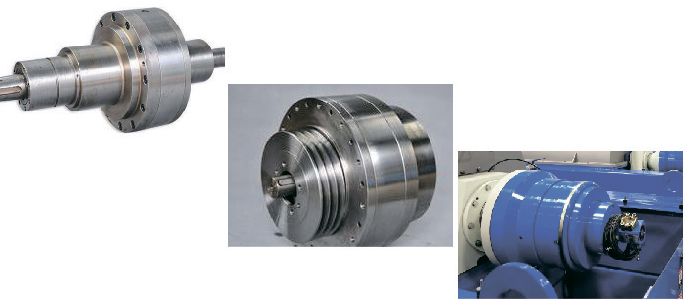

差速器

u 摆线针轮差速器

u 行星齿轮差速器

较大的扭矩输出

运行稳定可靠

u 液压差速器

较好的低差速输出

差速无级可调

紧凑的结构

Differential mechanism

u Cycloid pin wheel differential

u PIanetary gear differential

Larger torque output

Stable and reliable operation

u Hydraulic differential mechanism

Better Iow differential output

Differential stepless adjustable

Compact structure

密闭性能

u 轴封设计

确保工作腔与轴承腔之间有效隔离

u 出渣柔性接口与输送接口

按安装设计可以选配柔性接口或输送接口

Sealing performance

u Shaft seal design

ensuring effective separation between the working cavity and bearing cavity

u Flexible joint for slag discharge and transfer connection

Flexible joint or transfer connection for option of installation design

向心泵出液

u 液相通过向心泵抽出,液位可按工艺要求设定

u 整机密闭性好

Liquid phase to be discharged by centripetal-pump

u Liquid phase will be discharged by centripetal pump,with liquid level programmable as per process requirements

u Good sealing performance of the whole system

三相分离

u 应用于固-液-液分离

u 较重液相向心泵抽出(液面可调)

u 较轻液相转鼓溢流口溢出(液面可调)

Three-phase sparation

u Applicable for solid-Iiquid-liquid separation

u Heavier Iiquid to be discharged by centripetal pump (Liquid level adjustable)

u Lighter Iiquid to be overflowed via overflow port of the rotor drum (liquid level adjustable)

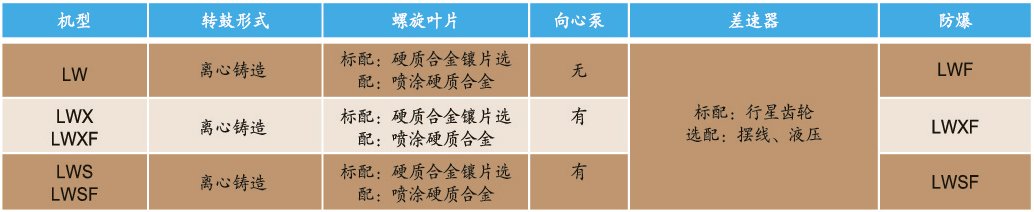

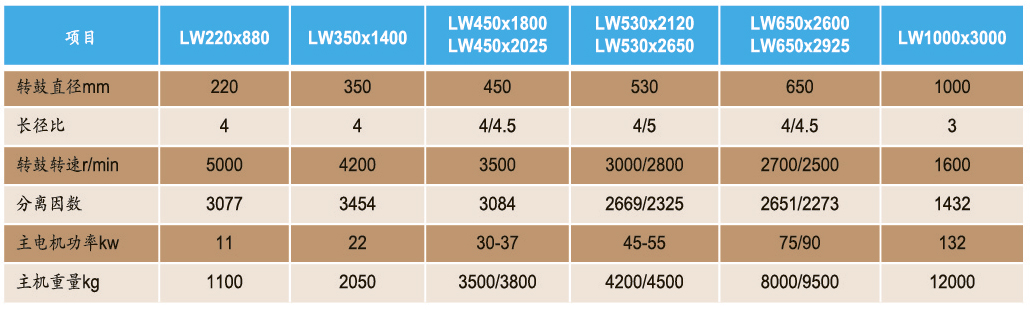

技术参数 Technical parameter

u LWX技术参数同上表

u 长径比上表中为常规参数,可按实际工况进行调整,以达到较为理想的分离效果

u Please refer to the Table above for technical parameters for LWX

u Ratio of length to diameter shown in above Table are generic parameter,which is subject to adjustment base on working conditions in order to achieve satisfying performance of separation.

防爆与密闭

u 整机密闭

u 轴封设计

u 氮气保护系统

u 出渣口接口

u 防爆/隔爆措施

(详见防爆技术应用)

Explosion-proof and sealing

u Sealing of the whole system

u Shaft seal design

u N2 protection system

u Slag discharge connection/joint

u Explosion proof and separation measures

(Refer to Application of Ex-proof Technology for detail)